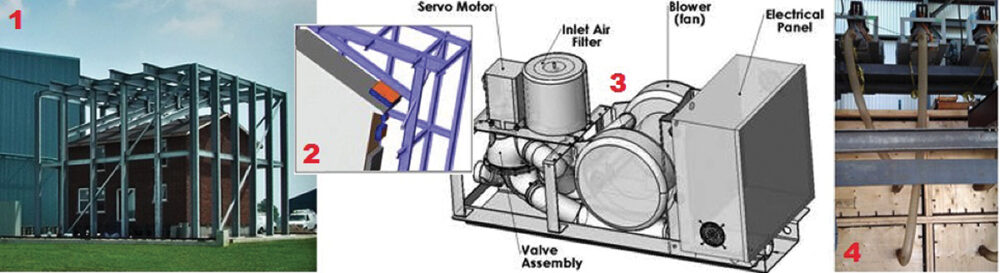

3LP Lab : 1. full-scale model inside reaction frame 2/4. reaction frame and pressure box arrangement 3/4. pressure loading actuator (PLA) system.

Services currently offered by the infrastructure:

The services available through the WindEEE Research Facility and associated Research Institute cover complete project lifecycle and required expertise, including but not limited to full-service operation of facilities and equipment (research-ready status), support for prototype and test apparatus fabrication, support for specific data acquisition and analysis, user training and connections/collaboration with a large group of researchers and industry partners.

The wind engineering group at Western University was established more than 50 years ago and contributed to countless engineering projects across the world ever since. The WindEEE Research Facility became operational in 2014 and, continuing the tradition of excellence and innovation, it is now a major contributor in the impact assessment of extreme wind systems (such as tornadoes and hurricanes) on the built-environment; renewable energy resource assessment and technology development; physical modelling of complex flow over urban canopies, topography and forestry; outdoor and indoor air quality and thermal comfort; wind-driven-rain, -snow and -debris; and fire and smoke propagations.

Our facilities average 315 Canadian and 185 international users per year.

DESCRIPTION OF WORK:

Access to WindEEE Research Facility’s 3D wind chamber and environmental loading lab at Western University (M1-36). The established unit of access is 1 business day (generally 9:00-17:00 but schedule shifts to accommodate time zone differences will be considered). The cost will be based on a combination of unit cost and actual cost.

Modality of access under this proposal:

Several user-groups will be granted access to the WindEEE Dome test chamber and/or the 3LP environmental loading lab. A typical TA project is estimated to span 15 days (15 units of access), usually the time interval for which the installation is considered to be exclusively reserved for the associated user-group. Generally, 7-8 days are dedicated to model fabrication and test setup while the remaining 7-8 days are reserved for the test execution, data archiving and documentation. The user(s) can be on-site for a portion or the entire 15-day timeframe, depending on their preferred involvement. Preliminary communication is expected to take place online.

The administrative and project management support will start immediately upon proposal acceptance and can span several weeks or months but, cost-wise, these tasks will be considered part of the setup time within the 15-day timeframe. Also, the unit cost will cover travel and accommodation for one user, required paperwork, training and full access to the facility (including staff support and equipment usage) for the entire on-site period. Given the potential for significant variation, the following costs are not included in the unit cost and they will be declared as actual cost:

- fabrication of test models and proxy structures (auxiliary test apparatus);

- access to personnel outside of WindEEE Research Facility;

- user travel and subsistence for additional users and/or beyond the on-site period.

This combination of unit and actual cost is the same one used for all (local or global) research projects at the facility in the past 7 years.

Support offered under this proposal:

Except areas that mandate specific consideration for safety and/or equipment operation know-how, the TA user decides the extent of their involvement and required support in all stages of the project.

Technical: Aside from equipment traditionally associated with wind engineering/research facilities (e.g., high resolution and high channel count data acquisition for pressure, strain, displacement, force, temperature, humidity; mobile weather monitoring system, etc.) WindEEE offers multiple cutting-edge technologies such as 3D/multi-hole flow probes, short-range LiDAR system, large-volume Particle Imaging Velocimetry (PIV) system and large-volume particle tracking and novel flow visualization capabilities. Advanced computational resources are available both on site and remotely. In terms of test model/apparatus fabrication, an advanced machine shop facility situated in campus complements the CNC hotwire (3D foam cutting fabrication) and CNC 4-axis router available on site. All technical staff will be available for on-site or remote project support.

Scientific: If requested, users have access to expert advice on a wide range of topics related to wind engineering, energy and environment. The members of WindEEE Research Institute, the Boundary Layer Wind Tunnel Laboratory and the Faculty of Engineering at Western University will be available for collaboration or consulting. Depending on the timeline, there is the possibility to observe and sometimes even participate in other projects taking place at the facility or partner labs on campus.

Administrative: The WindEEE administrative staff will help the users at all project stages including travel and accommodation arrangements, application for permits and any other required documentation. The support/communication will be initiated immediately after proposal acceptance and continued throughout the project.

Outreach to new users:

Highlights of on-going access as well as the call for proposal of new activities will be communicated through the social media channels and websites associated with the WindEEE Research Institute, the WindEEE Research Facility, Faculty of Engineering at Western University as well as several partner institutions across Europe. Past users and international researchers associated with the institute will be directly reached by email. In addition, all members of the Civil and Environmental Engineering department at Western University will be encouraged to advertise the program and the call for proposals via all hosted or attended events that could reach potential users.

Review procedure under this proposal:

For details on the TA evaluation process, please refer to Task 1.2 of WP1 and the process followed by the TA-SEP in particular.